End Booms are available in several lengths (3′, 13′, 23′, 32′, 42′, 51′, 61′, 85′ and 105′). Truss rods and inverted truss supports provide the primary support for strength and stability. The 6″ sand trap and control box, for the optional booster pump, are located near the tower for ease of servicing. The booster pump itself is located at the end gun for maximum efficiency.

Swing Arm Corners

The Swing Arm Corner System (SAC) lets you get more irrigated acres without buying more land or setting up a new water system. Our exclusive swing span design provides uniform application of water and chemicals and can be retrofitted on existing Reinke systems or on many competitor systems.

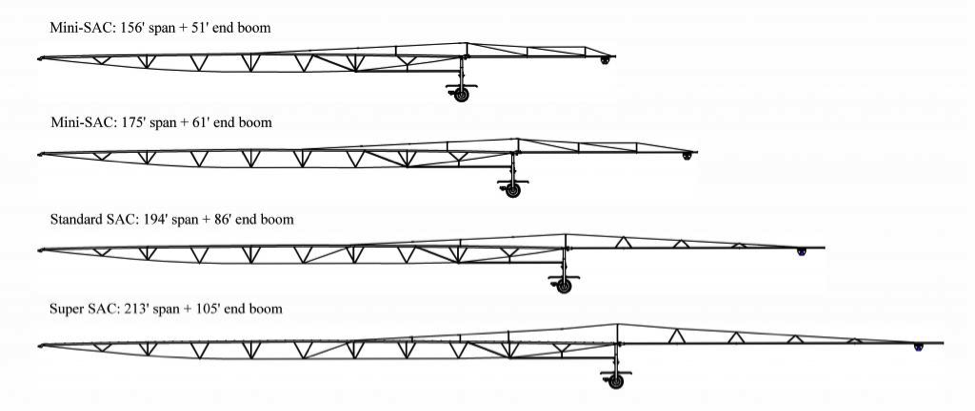

The SAC allows operators to change the orientation to either a “leading” or “following” position to increase the number of irrigated acres in part circle applications. Reinke offers the following Swing Arm Corner sizes:

- Mini-SAC: Featuring a 156′ span and 51′ end boom. Provides 207′ of coverage (approximatley 297′ with end gun)

- Mini-SAC: Featuring a 175′ span and 61′ end boom. Provides 236′ of coverage (approximately 326′ with end gun)

- Standard SAC: Featuring a 194′ span and 86′ end boom. Provides 280′ of coverage (approximately 370′ with end gun)

- Super SAC: Featuring a 213′ span and 105′ end boom. Provides 318′ of coverage (approximately 408′ with end gun)

Options

- Navigator GPS – with Real Time Kinematic (RTK) surveyor-grade equipment, the Navigator series of GPS controls provides extreme accuracy in timing and application

- Accu-Corner – Assures even, accurate application throughout the corner. Minimizes over/under watering: Programmable logic controller, 12 groups of sprinklers and up to 61 programmable stages, Unique operator interface. NOTE: The Accu-Corner is not available with the Mini-SAC offerings.

- Exclusive Patented Energy Saver Package (ESP) – Utilizes an extra sprinkler package with automatic valves to supply additional water, instead of needless pressure during the retraction cycle of the swing arm corner. Save hundreds of dollars every season with each system revolution. See chart.

Diesel Fuel Cost Savings with ESP

| 1000 GPM Pumping Unit | Without ESP | With ESP |

|---|---|---|

| System GPM Extended/Retracted | 1,000/590 | 850/850 |

| System GPM Transition Phase | 590-1,000 | 660-1,010 |

| GPM/ Acre | 4.7 | 5.6 |

| Hours to Apply 1" | 96.1 | 86.9 |

| Pumping Depth (feet) | 120 | 120 |

| Horsepower Hours to Apply 1" | 6,609 | 5,935 |

| Diesel Fuel Cost to Apply 1" | $1,212.40 | $1,089.20 |

(Annual savings based on 12″ per year: $1,478.40. Assuming diesel fuel at $3.50 per gallon and consumption at .36 LB/HP*HR)

And remember all of Shoemaker Irrigation’s Residential, Commercial and Agricultural Systems are supported by state-of-the art drainage systems including options for ADS piping, NDS valve boxes as well as NDS drainage boxes. There is no problem too big for Shoemaker Irrigation’s solutions!